Our blm skidding units are installed above the main deck and are based on the same proven technology used in our jackup elevating systems.

Electric rack pinion jacking system.

Electric rack pinion jacking system hydraulic rack pinion jacking system cylinder jacking system.

However one of the well known methods of elevating the jack up hull is rack and pinion.

Liftboat with jacking legs.

There is a multiple jacking system on the jack up rigs used.

For high speed operation and deep water application rack and pinion systems are preferred.

The gustomsc rack pinion system offers jacking speed up to 0 8 m min and leg handling speed up to 1 2 m min therefore the jacking operation is no longer the decisive factor during a rig move.

Rack and pinion skidding systems are used for moving the cantilever and the drill floor of a jackup rig to locate the well center at correct position.

Designed and built in compliance with abs dnv rules for self elevating platforms vessels.

Abb s jacking packages are designed to drive rack and pinion jacking systems.

Abb jacking power system.

Jacking system for jackup rigs we have a full range of elevating units with lifting capacities from 50 to 455 metric tons per pinion.

We can offer bespoke rack lengths and movements multiple jacks in a set operated via one handle.

Cost effective and reliable system for over 100 vessels worldwide.

Capable of lifting a load upwards of 93 600 kips.

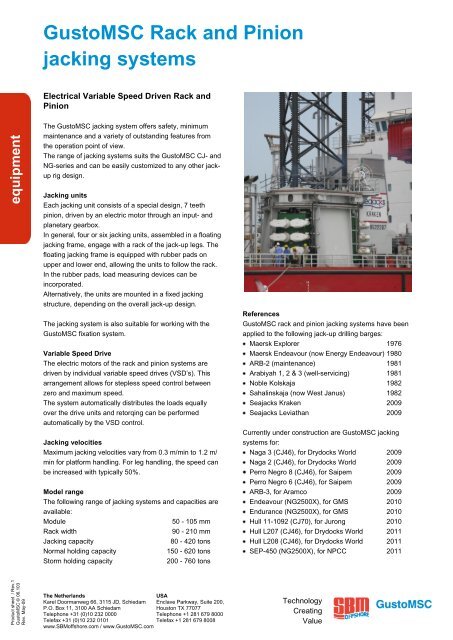

Each jacking unit consists of a special design 7 teeth pinion driven by an electric motor through an input and planetary gearbox.

Rack and pinion jacks are ideal to push pull lift and lower loads.

In general four to eight jacking units engage with a rack of the jack up leg.

Abb provides a complete jacking power system including power distribution jacking drives and motors.

Patented load sharing devices ensure equal load distribution over the pinions increasing safety and lifetime of the jacking system.

The electric motors of the rack and pinion systems are driven by siemens individual variable speed drives.

Hydraulic rack and pinion systems in the range of 500 to 2 000 tons per leg contain in house fabricated motors power units and control systems using standard or tailor made components.

Hand or motor driven.

Our systems can elevate the hull into position for drilling operations and for raising and supporting the legs while the rig is afloat.

This arrangement allows for step less speed control between zero and maximum speed.

Used in compression or tension these jacks are very diverse.

The jacking units can be mounted in a floating frame or can be mounted directly into the fixed jacking structure depening on the jack up design.